The new Metro Waste Authority (MWA) MRF processes 25 tons per hour of single-stream recycling from more than 100,000 residents in the Des Moines, Iowa metro area.

Establishing a State-of-the-Art Recycling Operation

To create a successful operation, MWA emphasized advanced technology, a commitment to education and strong industry partnerships.

System Vision

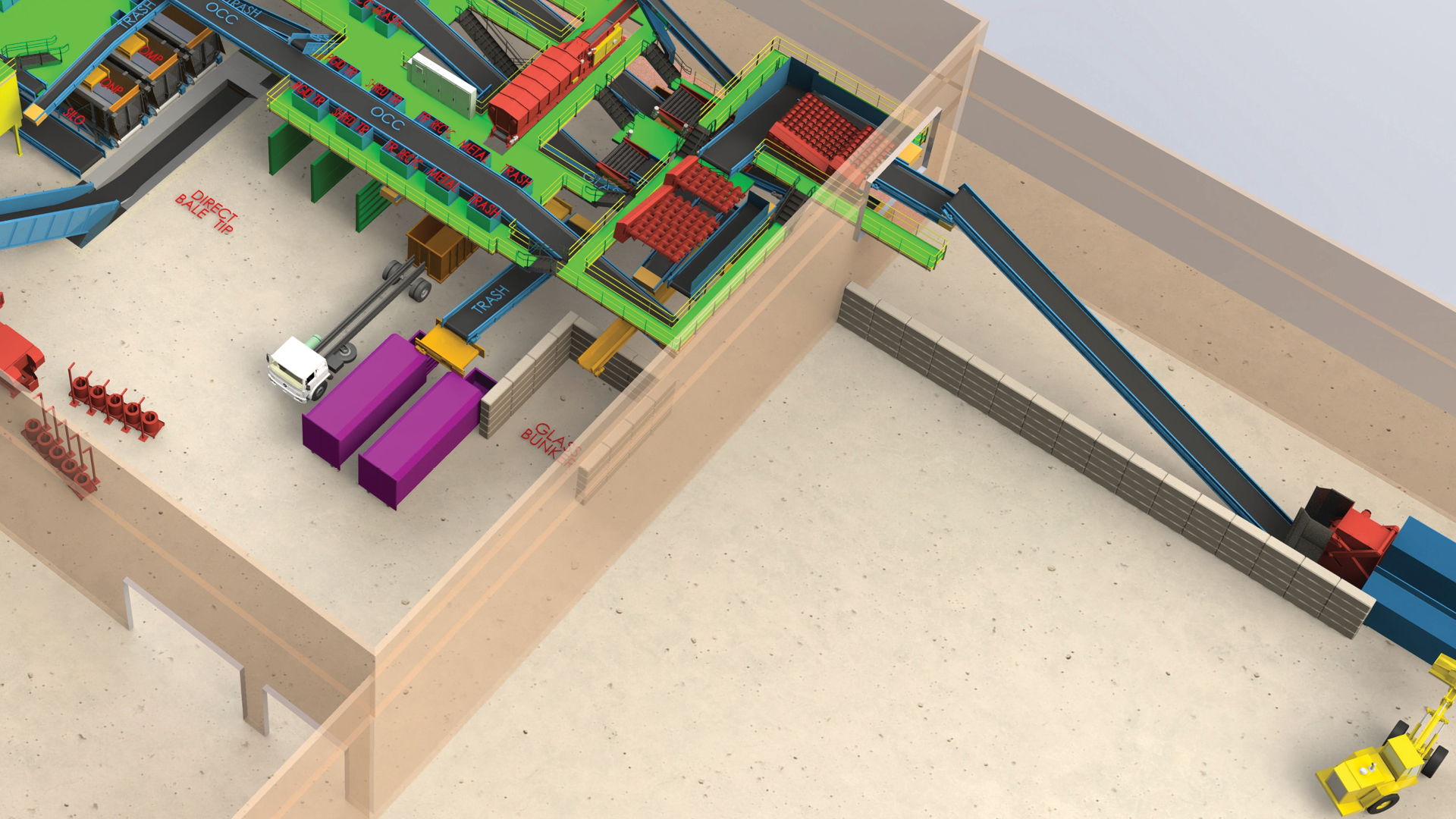

CP Group was selected to provide the innovative sorting system: one that would capture more material, reduce contamination and provide safe working conditions.

Fractionate, Liberate, Separate

MWA’s new, innovative system follows the design CP Group’s design principles for the successful recovery of commodities with lower operating costs.

Eliminate the Presort

CP has pioneered their newest machine, the Auger Screen, in a single-stream environment to eliminate presorting. This means MWA’s process requires no traditional presort.

Primary Auger Screen

This non-wrapping machine fractionates material, increasing sorter safety by removing small fraction, including contamination like needles and sharps.

OCC Auger Screen

MWA is the first residential facility with patented non-round augers, which agitate material and create clean OCC product, omitting the need for an OCC screen.

OCC Quality Control

The overs of the OCC auger screen go to a combined postsort/OCC QC. This eliminates the need for multiple sorters and sort stations.

Small Fraction/Glass

The unders of the 6” primary auger screen go to a glass breaker, which removes the fines. These discs are specialized, long-lasting cast-chromium steel discs.

CP LightsOut™

This air drum separator for glass processing is very low maintenance and uses air to remove contaminants from glass.

CP Screen Liberates 2D from 3D

By agitating materials with high amplitude disc screens, glass and dirt fines are liberated from the commodities and captured by the third cut on the CP Screen.

MSS CIRRUS FiberMax™ for ONP

These high-volume optical sorters have belt speeds processing at 1,000 feet per minute with the capability of more than 1,000 picks per minute, the fastest in the industry.

MSS CIRRUS PlasticMax™

Optical sorting separates and recovers polyethylene terephthalate, high-density polyethylene and mixed plastics with minimal manual sorting.

Low Maintenance / High Performance

This system emphasizes low maintenance, utilizing non-wrapping cantilevered auger screens and anti-wrapping disc screens to fractionate/liberate material and high-capacity optics to make yes or no decisions.

The Result

The system is performing exceptionally well, reducing contamination early in the sorting process, allowing MWA to produce great output for material sales.

Interactive Education Center

The education center features an exhibit space that includes kiosks, infographics and a hands-on sorting activity where visitors of all ages can learn about recycling.

Engaging Art Installation

The center also boasts a vibrant mural designed by a local artist, an observation deck above the sorting floor and multipurpose space for community meetings.

Enclosed Tip Floor

The tip floor spans 27,600 square feet and is completely enclosed to prevent blowing litter and protect the material from rain and snow.

This facility will improve recycling and benefit metro communities throughout the state for years to come.