CP Auger Screen™

Anti-Wrapping Sizing Machine

Eliminate the Presort

The presort is the most dangerous sorter position in a MRF. Sharps, biohazards, glass, needles and other materials hidden under a large burden depth of material move quickly creating a dangerous and dizzying position. When these sorters need to slow down the line to remove large items, system productivity goes down.

Our solution to this problem is to eliminate the presort.

The CP Auger Screen™ is a first of its kind machine used as a primary fractionating screen in single stream. It diverts 60% or more of the inbound material away from the traditional presort.

Primary Separation Solution

CP Group completed a total system upgrade at Cal-Waste in Galt, California that involved adding a Primary Auger Screen. Dave Vaccarezza, owner of Cal-Waste, says the Primary Auger Screen, “takes the burden depth down to a much more manageable level and does a great job of spreading everything out so there are no big lumps and clumps.” It also allowed Cal-Waste to reduce the number of sorters on the Auger post sort line from eight to four. Additionally, the MRF increased its capacity from 11 to 30 tons per hour.

Additional Solutions

OCC Auger Screen

- Durable steel cantilevered tri-lobe augers

- Non-wrapping, self-cleaning, and low maintenance

- High agitation and throughput

- Eliminates the presort enhancing worker safety

CP Auger Screen for C&D

- Extremely low wrapping and jamming

- Low maintenance, minimal wear

- Reliable sizing at high volume

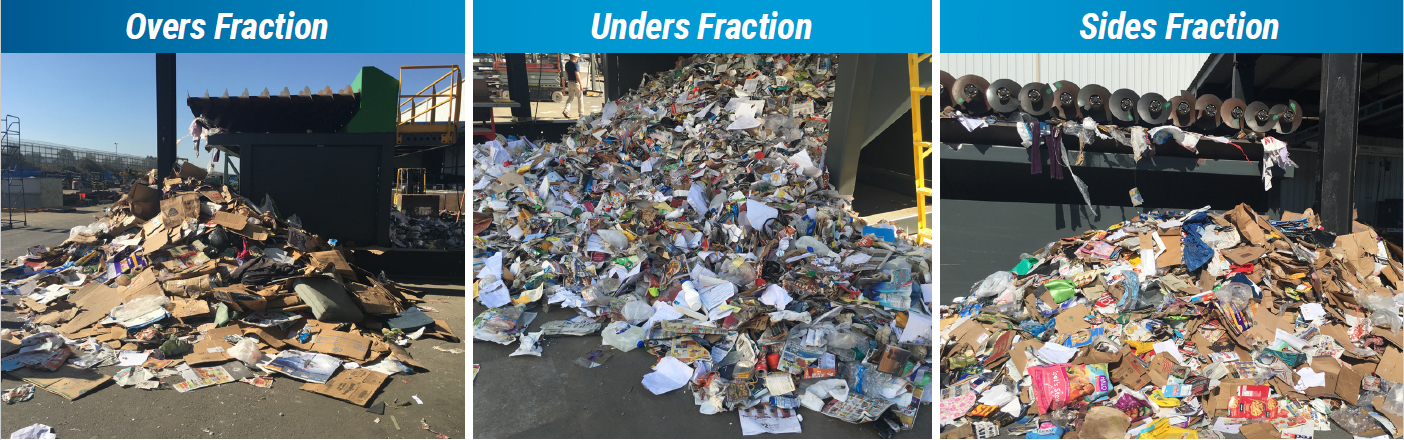

- Produces three cuts from one stream: overs, unders, and sides

- Screens out fines and reduces the burden depth on the belt to help keep workers safe

Anti-Wrapping Screen with

Low Wear and Maintenance

The revolutionary CP Auger Screen™ sizes material by using a series of cantilevered augers that mitigate wrapping and jamming, and requiring very low-maintenance. Built with low-wear technology, it maintains reliable sizing at high volumes for Single Stream, MSW, C&D, C&I, and Green Waste applications.

Primary Separator

Scalping Screen

Fines Screen

Adjustable Opening Sizes

Primary Separator

- Decreases amount of material seen by sorters, increases efficiency

- Removes small fraction from sorters, increases safety

- Decreases amount of manual sorters needed, only see the “Big Uglies”

Scalping Screen

- Creates homogenous sized streams to properly feed downstream machines

- Captures small OCC (Amazon effect) in one place for better recovery of OCC

Fines Screen

CP Auger Screen process MSW

at Hampden, Maine facility

CP Auger Screen process MSW at Boston facility

CP Auger Screen Processing Single Stream Material

CP Auger Screen Process Stringy, Dry Commercial, and C&D Material

CP Auger Screen™ Features

-

Extremely low wrapping and jamming

-

Reduces manual sorters

-

Low maintenance, minimal wear

-

Three cuts: Overs, Unders, and Sides

-

Reliable sizing at high volume